|

Multi-Brand multi-brand spare parts (plates / gaskets)

FLFA has its own heat exchanger sheet and gasket factory in China, which can provide world famous brands (brands include: SPX / SPX, Ampere / APV, GEA / GEA, SWEP/SWEP, Sanders/SONDEX, Eppel Schmidt/API.Schmidt, Fengkai/FUNKE, Samoweifu/Thermowave, Vikpo Vicarb, Donghe Entai/DONGHWA, Ike The detachable plate heat exchangers of ACCESSEN, MULLER, FISCHER, REHEAT, etc., replace the plates and gaskets, and the models are nearly a thousand, achieving a complete replacement with the brand plate heat exchanger accessories. Plate heat exchanger customers in different countries and industries around the world are using FLFA's heat exchanger accessories and are working well. Multi-Brand Multi-Brand Maintenance Service — OEM value Regardless of the brand of plate heat exchanger installed in your facility, the performance on the OEM nameplate can be achieved. The FLFA Service Center wants to ensure that you continue to enjoy the performance noted on the nameplate. With our fast, economical and reliable service, your heat exchangers can achieve low downtime and reliable maintenance. To this end, we offer OEM-quality spare parts and services for every plate heat exchanger you use, including APV Ampere, SPX, Kelvion, GEA GEA, SWEP, Sondex, Danfoss, Vicarb, Funke, Thermowave, and Thermowave, all FLFA equipment will be able to enjoy genuine FLFA OEM spare parts and services . For FLFA heat exchangers, you get more services. We track the original design conditions based on the serial number on the heat exchanger nameplate you are using to confirm that the product information is authorized. For faulty equipment: We will check your current operation to understand the cause of deterioration, expansion or breakage of the gasket and then replace the gasket We will provide the correct bonding method, replacing the cracked and leaking gasket with a new gasket. We will provide the correct sealing practices to prevent over-tightening and damage to the plates. With FLAF and its authorized service locations, you always have access to the right gaskets and plates as well as friendly service and our OEM guarantee. — Field Service Field service personnel at the FLFA Service Center can restore your plate heat exchanger to the nameplate at any time. Whether it's a planned downtime or emergency service, OEM spare parts and services will benefit your heat exchanger. The service center is based on FLFA's global engineering resources, including design, application and materials engineering, to successfully complete tasks. New spare parts used in all our on-site work will be covered by a one-year warranty and include process and labor costs. On-site services include:

• Renovation of the bundle (open and assemble the heat exchanger, pressure clean the plate, visually inspect the plate, inspect the gasket and replace as needed)

• Slab exchange

• Water pressure / pipeline testing of heat exchangers

• Troubleshooting

• Send pick-up (for work that needs to be done at our factory)

Our personnel can also provide cleaning services for most brands of welded plate heat exchangers other than FLFA products. If the channel is accessible, pressure cleaning is usually used to remove most of the contaminants.

FLFA technical service personnel are certified by the relevant country.

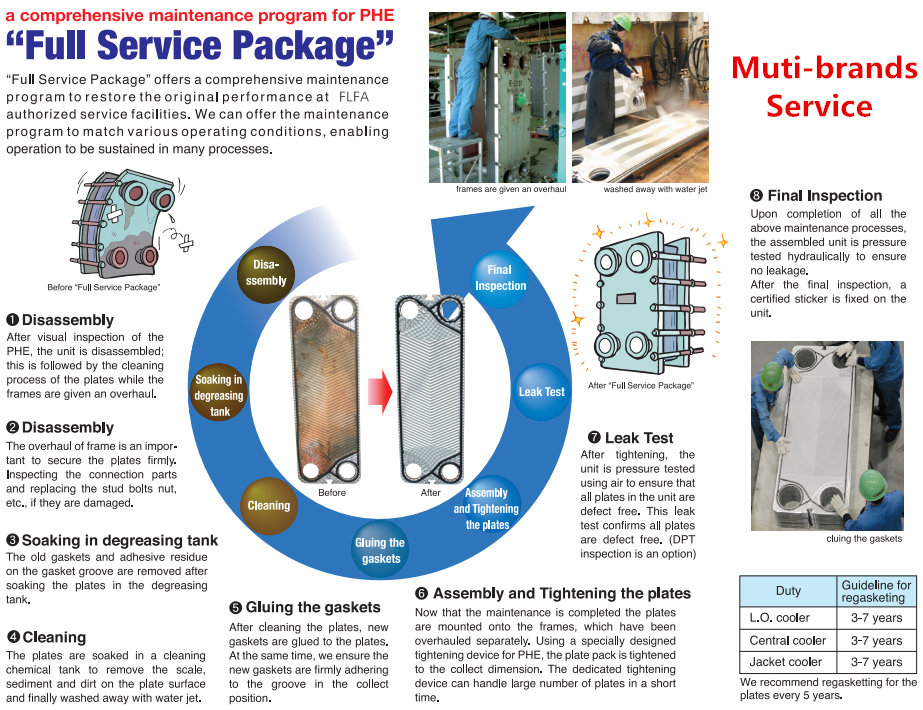

— On-site maintenance and return to factory maintenance Although the plate type heat exchanger is durable, after long-term use, it is difficult to maintain the original performance due to deterioration of the seal ring, adhesion of the stain, and the like, and various problems such as liquid leakage may occur. In order to make the plate heat exchanger usable in a long-term, stable, and good condition, regular maintenance is indispensable.

While ensuring the inventory of various replacement parts such as seals, FLFA also provides a wide range of services according to the needs of customers, such as dispatching skilled technicians for on-site maintenance and “returning factory inspection and renovation”. Package service" and more.

FLFA has accumulated a wealth of technical experience and has spread advanced heat transfer plate technology to the world. Such a FLFA can provide “reliable” and “trusted” maintenance services.

If you don't pay attention to maintenance for a long time...

Dismantling cleaning service plan

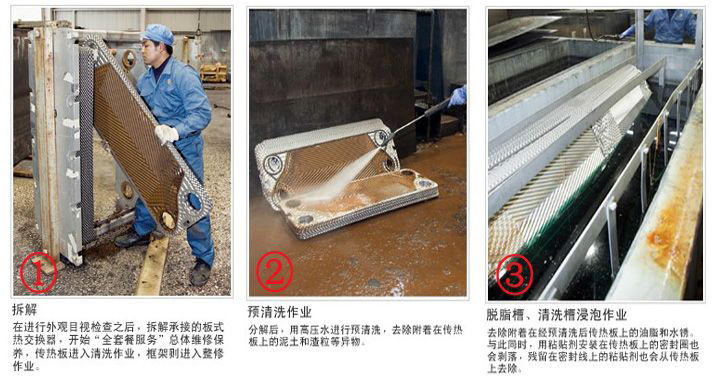

In order to maintain the customer's plate heat exchanger in a good state, FLFA has provided a wide range of service menus such as “disassembly, cleaning”, “improvement of operations” and “local service” with years of accumulated technical experience to carry out maintenance and repair services.

The maintenance service is mainly based on “returning factory inspection and refurbishment” and “on-site cleaning and maintenance”. The “recovery factory inspection and refurbishment” takes the customer's plate heat exchanger host back to the maintenance and returns it after recovery. “On-site cleaning and maintenance” is the professional engineer of the company carrying professional equipment to the user's site to carry out the work, the time is short, the efficiency is high, and the customer's production and operation will not be delayed. In addition, a variety of service menus such as consultations are available to help customers maintain the state of the plate heat exchanger.

Customers can choose the type of service based on usage conditions and conditions, so there are many ways to maintain the machine's operating status.

Disassembly cleaning and maintenance steps:

|

|

Which type of heat exchanger is right for you?

Where can I get a quotation?

How to inquire?

Please contact your local contact for more information. In addition, please email us at any time.

Contact Us >>Copy right © 2018 FLFA HEAT EXCHANGERS UK LTD

ICP: SU ICP 18037353