Our FLFABlock plate and frame heat exchangers are a compact, long-lasting solution for challenging aggressive media, extreme temperatures and/or high pressure applications. Because FLFABlock heat exchangers do not have exposed gaskets, they can replace shell and tube heat exchangers and cover the same conditions, but have many advantages in terms of cost, size and performance.

Product description

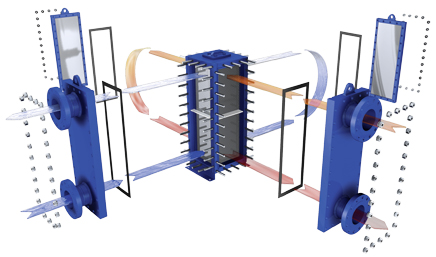

FLFABlock plate and frame heat exchanger

Our FLFABlock heat exchangers are designed for challenging applications that require high thermal performance and require aggressive media, extreme temperatures and/or high pressures. This type of customer is usually solved with a large, ineffective shell and tube heat exchanger. However, FLFABlock heat exchangers offer good thermal performance and other significant advantages over their outer casing and tubular construction. Plate and frame heat exchangers generally mark the beginning of a new era of efficient heat transfer, even for challenging applications.

What does this mean for you?

Because FLFABlock heat exchangers are based on board technology rather than tube technology, they require less surface area to increase efficiency. The higher heat transfer coefficient achievable with the plates allows our engineers to create a heat transfer solution that greatly reduces installation space requirements and reduces the weight compared to shell and tube heat exchangers.

If you need a heat exchanger made of titanium alloy, nickel-based alloy or other foreign materials, the compact design of the FLFABlock greatly reduces the cost per unit, the same as the shell-and-tube heat transfer.

At the heart of the FLFABlock is a fully welded flat pack. The corrugated plate pattern creates turbulent flow, greatly reducing the risk of fouling and greatly improving the performance of the heat exchanger, making the FLFAblock heat exchanger an ideal choice for challenging tasks.

The slab also provides uniform flow distribution and good surface utilization, especially if the heat exchanger needs to be a multi-channel solution.

Simple, infrequent maintenance and cleaning

In addition to poor thermal performance, another disadvantage of shell-and-tube heat exchangers is the need for frequent cleaning, resulting in severe production losses. The FLFABlock heat exchanger is not susceptible to contamination and clogging and requires only occasional inspection and cleaning.

Maintenance and cleaning time is small and space is large, as all panels on the heat exchanger can be easily removed. The entire board can be accessed from all sides without additional space.

Features and benefits

The perfect condenser can be configured to handle or not contain condensate work. A FLFABlock heat exchanger is also a good choice. It is a steam heater or heavy boiler for non-circulating operation and a smooth and stable steam control system.

A very durable heat exchanger that specializes in handling aggressive and fouling media. The ability to handle aggressive media on both sides is an ideal solution for crude oil refineries and petrochemical plants. Ideal for challenging missions.

The production is increased due to the extended uptime of the heat exchanger. Very low maintenance and service requirements. The detachable side panels provide quick and easy access to the panel for inspection or cleaning.